Insulating Castables for Efficient High-Temperature Applications

About Insulating Castables

Unshaped refractory products, such as Insulating Castables, are essential for modern industrial processes, providing superior thermal insulation, easy installation, and reliable performance in extreme operating conditions. At Mahakoshal Refractories Pvt. Ltd. (MRPL), we specialize in manufacturing and supplying premium Insulating Castables refractories designed for kilns, preheaters, coolers, and clinker formation zones, ensuring energy efficiency, operational reliability, and long-term durability.

Our castables are formulated using high-quality raw materials sourced from captive mines and trusted global partners, combined with advanced in-house binder production. This ensures excellent thermal shock resistance, low density, and minimal heat loss, making them ideal for lining high-temperature zones. Complemented by high alumina bricks and refractory castables for Insulating Castables kilns, MRPL offers complete, cost-effective solutions that enhance furnace efficiency and reduce energy consumption.

Additionally, we provide application-specific unshaped solutions, including silicon carbide castables for abrasion resistance and refractory plastics for complex geometries. Our adaptable Insulating Castables are widely used across steel, cement, petrochemical, power, and aluminium industries, delivering optimized performance and reduced operational downtime.

Serving Industries with Insulating Castables.

MRPL’s Insulating Castables refractories are engineered for industries demanding thermal efficiency, durability, and high-performance refractory linings. Our unshaped castables, supported by high alumina bricks and refractory castables for Insulating Castables kilns, optimize heat retention and reduce energy consumption. These solutions are ideal for steel, cement, glass, petrochemical, power, and aluminium industries, providing reliable performance in kilns, preheaters, coolers, and clinker formation zones. As a trusted refractory manufacturer for Insulating Castables, MRPL delivers tailored, cost-effective solutions that enhance furnace life, minimize downtime, and boost overall operational efficiency.

WhatsApp UsOptimize Thermal Efficiency with MRPL Insulating Castables Refractory Solutions

Benefits of MRPL Refractories for Insulating Castables

High Thermal Shock Resistance

MRPL refractory solutions for Insulating Castables withstand rapid temperature changes reliably.

Energy Efficiency

Low-density Insulating Castables refractories minimize heat loss, optimizing kiln and cooler

Cost-Effective Performance

Durable refractory castables for Insulating Castables kilns reduce maintenance and operational costs.

Lightweight & Easy Installation

Our Insulating Castables refractories allow faster installation with minimal downtime and labor.

Get in Touch

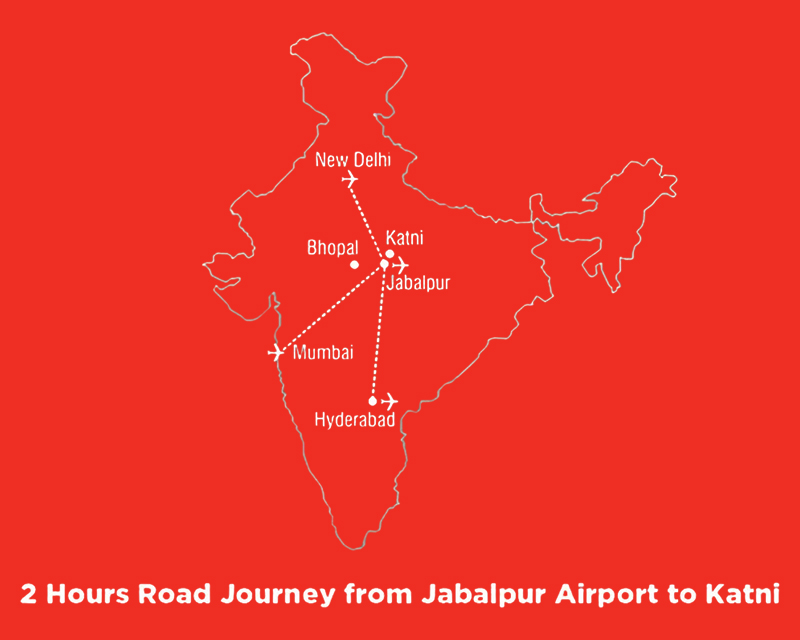

At Mahakoshal Refractories, we value every connection. Whether you’re looking for product information, technical support, or business collaboration, our team is ready to assist you. Get in touch with us through phone, email, or the form below – we’ll respond promptly to your requirements.