Reliable Fire Clay & High Alumina Mortars (Air Setting) for Industrial Applications

About Fire Clay & High Alumina Mortars( Air Setting )

Mahakoshal Refractories Pvt. Ltd. (MRPL) is a trusted refractory manufacturer for Fire Clay & High Alumina Mortars (Air Setting) delivering unshaped refractory solutions that ensure excellent performance, durability, and thermal efficiency in extreme industrial environments. These air setting mortars are specifically designed for joining high alumina bricks, refractory castables, and insulation materials used in kilns, preheaters, coolers, and clinker formation zones.

Our Fire Clay & High Alumina Mortars (Air Setting) are formulated with precision using high-purity raw materials sourced from our captive mines. They offer superior bonding strength, low shrinkage, and excellent thermal shock resistance, ensuring long-lasting refractory structures that withstand mechanical and thermal stress.

MRPL’s advanced formulation technology and strict quality control standards ensure each batch of mortar meets global refractory performance benchmarks. Our air setting mortars enhance operational reliability, reduce downtime, and deliver refractory solutions for Fire Clay & High Alumina Mortars (Air Setting) kilns that are energy-efficient, cost-effective, and built for longevity.

Serving Industries with Fire Clay & High Alumina Mortars( Air Setting ).

MRPL’s Fire Clay & High Alumina Mortars (Heat Setting) serve a wide range of industries requiring reliable and high-performance unshaped refractory solutions. Designed for applications in kilns, preheaters, coolers, and clinker zones, our mortars ensure exceptional bonding, energy efficiency, and long service life. As a leading refractory manufacturer for Fire Clay & High Alumina Mortars (Heat Setting), MRPL supports industries such as steel, cement, petrochemical, aluminium, power generation, and non-ferrous metal processing with customized, durable, and cost-effective refractory solutions that withstand the toughest operational environments while maintaining consistent structural integrity.

WhatsApp UsBuild Stronger, Longer-Lasting Refractory Linings with MRPL Fire Clay & High Alumina Mortars (Air Setting)

Benefits of MRPL Refractories for Fire Clay & High Alumina Mortars (Air Setting)

Exceptional Bonding Strength

Ensures durable adhesion between high alumina bricks and refractory castables under high temperatures.

Superior Thermal Resistance

Delivers long-term refractory solutions for Fire Clay & High Alumina Mortars (Air Setting) kilns and furnaces.

Energy Efficiency

Enhances heat retention and reduces fuel loss, optimizing operational energy consumption.

Cost-Effective Longevity

Minimizes maintenance frequency while ensuring consistent performance and extended refractory life.

Get in Touch

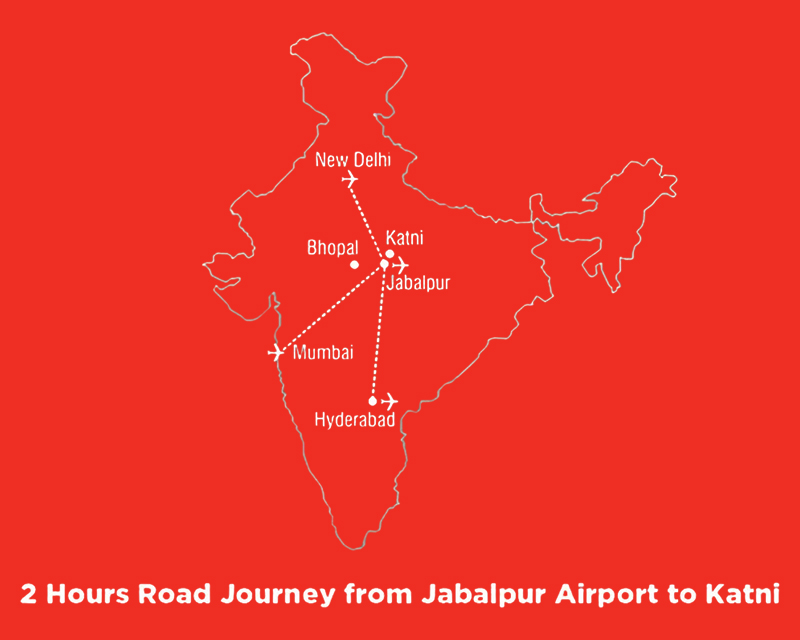

At Mahakoshal Refractories, we value every connection. Whether you’re looking for product information, technical support, or business collaboration, our team is ready to assist you. Get in touch with us through phone, email, or the form below – we’ll respond promptly to your requirements.