Expert Refractory Solutions for the Power Sector

Durable, Efficient, and High-Performance Refractory Materials

Mahakoshal Refractories Pvt. Ltd. supplies a wide range of refractory products for various critical areas of Power Plants, especially CFBC and AFBC boilers, ensuring maximum durability, thermal efficiency, and operational reliability.

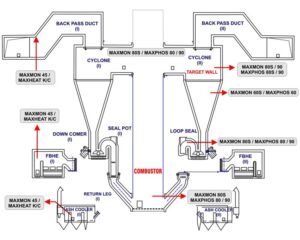

Our products are designed to perform under extreme temperature and erosion conditions found in combustion and flue gas zones. We provide engineered refractory solutions for the following key areas:

- Combustor & Return Leg – High-performance MAXMON 80S / MAXPHOS 80 & 90 castables to withstand direct flame and high abrasion zones.

- Loop Seal & Seal Pot – Durable MAXMON 80S castables ensuring smooth operation and resistance to alkali attacks.

- Cyclone & Target Wall – MAXMON 60S / MAXPHOS 60 formulations offering superior resistance to thermal shocks and particle erosion.

- FBHE (Fluidized Bed Heat Exchanger) & Down Comer – MAXMON 45 / MAXHEAT K/C castables ensuring stability in heat transfer and ash handling sections.

- Ash Cooler – Reliable refractory linings designed for mechanical and thermal wear resistance.

- Back Pass Ducts – MAXMON 80S / MAXPHOS 80 & 90 castables ensuring protection from hot flue gases and dust-laden streams.

With our comprehensive range of castables and insulating materials, Mahakoshal ensures longer service life, reduced downtime, and efficient thermal management in power plant operations.

Our continued supply and proven performance across numerous installations reaffirm Mahakoshal’s position as a trusted partner for refractory solutions in the power generation sector.

Key Refractory Application Areas in Power Plants.

Refractories are essential in power plants to protect equipment, enhance efficiency, and maintain continuous operation. MRPL provides specialized refractory solutions designed to withstand high temperatures, chemical corrosion, and mechanical wear in critical zones. Our products improve durability, energy efficiency, and overall plant reliability. Power Sector refractories are used across boilers, furnaces, kilns, preheaters, and cooling systems to ensure stable operation and minimal interruptions.

WhatsApp UsBoost Power Plant Efficiency with MRPL Refractory Solutions

Benefits of Procuring Refractory Products from Mahakoshal Refractories

Own Mines

Own mines for sourcing clay and bauxite with strict quality control.

In-house Manufacturing

In-house manufacturing of high alumina cement for various castable grades.

Advance planning and sharp delivery commitments

Advance planning and sharp delivery commitments ensuring on-time dispatch – often up to ahead of schedule.

Real-time Shipment Updates

Real-time shipment updates keeping customers informed throughout transit.

Reliable & Transparent Service

Reliable and transparent service at every stage of the supply process.

Quick & Efficient Response

Quick and efficient response to customer needs and requirements.

Strong Focus On Customer Satisfaction

Strong focus on customer satisfaction with complete post-delivery support.

Trusted Partnership

Trusted partnership built on timely delivery, quality assurance, and long-term reliability.

Why Power Plants Trust MRPL Refractories

Proven Experience

Decades of providing specialized refractory solutions to power generation industries worldwide.

Quality Assurance

Rigorous testing ensures durable, high-performance, and thermally stable refractory products consistently.

Customized Design

Tailored refractory solutions meet unique operational requirements for maximum plant efficiency.

On-Time Delivery (OTIF)

Efficient production and logistics guarantee timely supply of refractory materials reliably.