Refractory Solutions for Aluminium Industries

Efficient & High-Performance Refractory Solutions for Aluminium Industries

Mahakoshal Refractories Pvt. Ltd. is one of the leading suppliers of refractory products to the Aluminium Industry, providing reliable solutions for a wide range of high-temperature applications. Aluminium production processes involve continuous exposure to molten metal, corrosive fluxes, and rapid temperature fluctuations, demanding refractories with excellent thermal stability, non-wettability to molten aluminium, and strong resistance to erosion and corrosion.

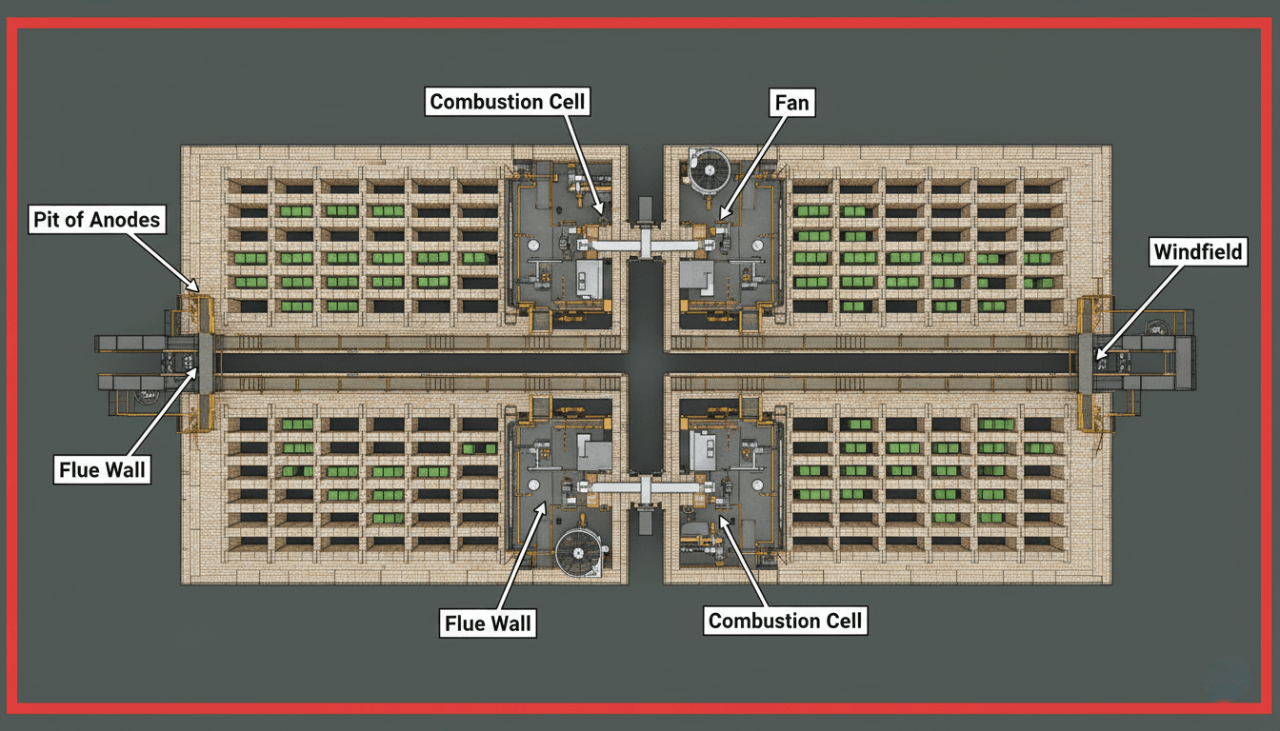

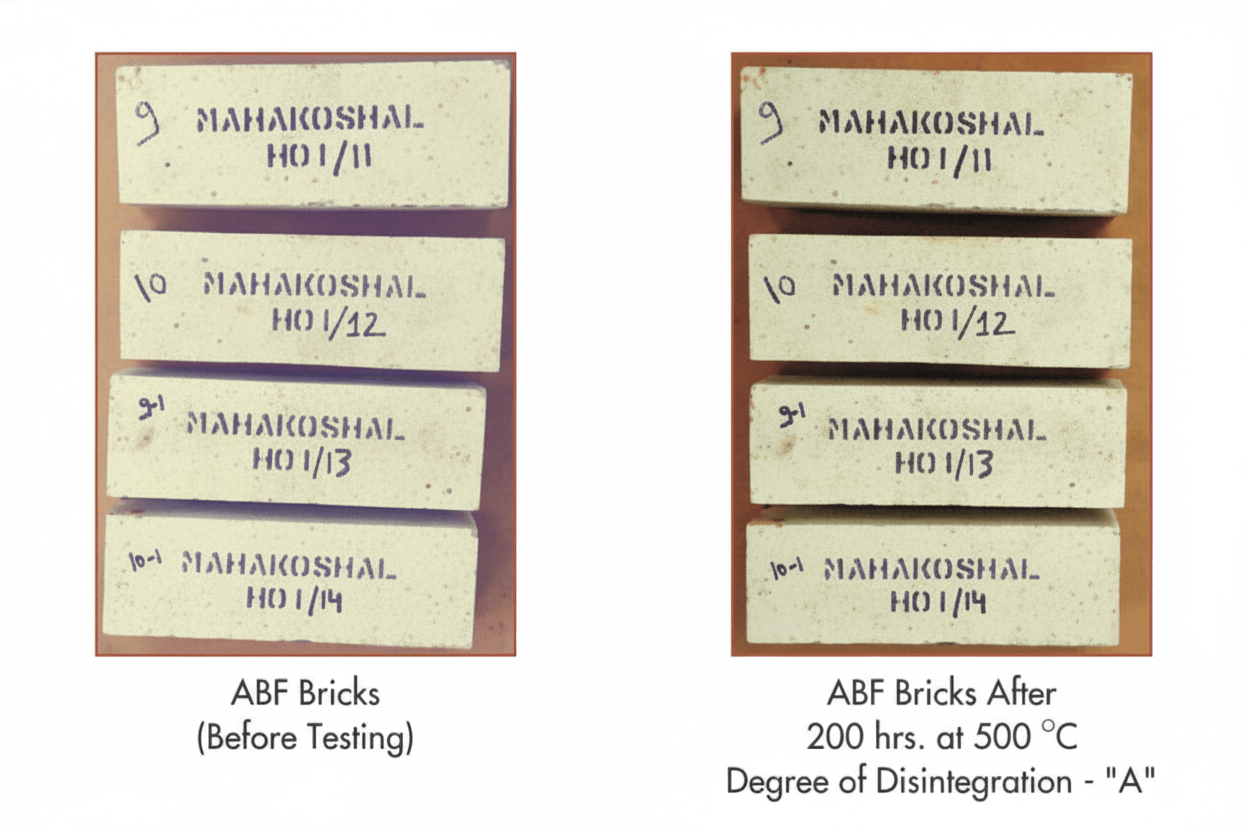

Mahakoshal is a trusted supplier to major Aluminium plants, regularly catering to critical application areas such as the Anode Backing Furnace, Holding and Melting Furnaces, and Pot Furnaces.

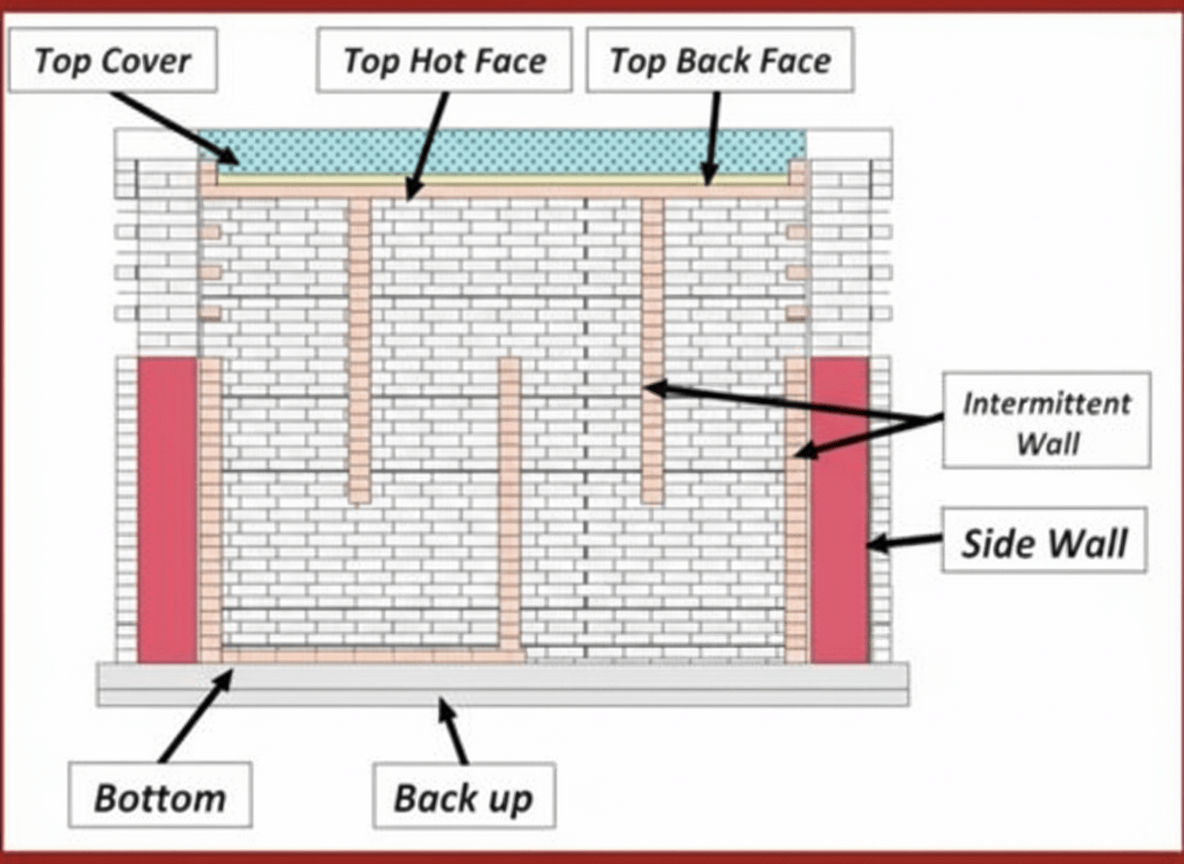

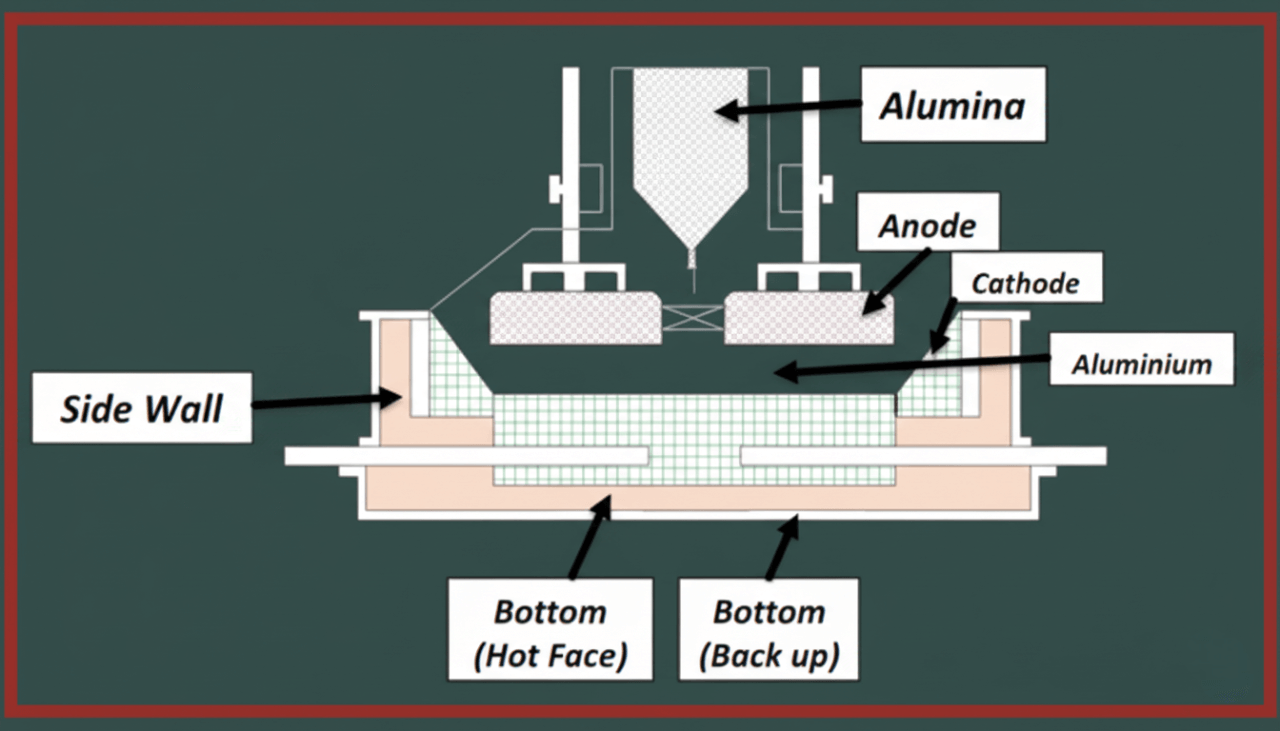

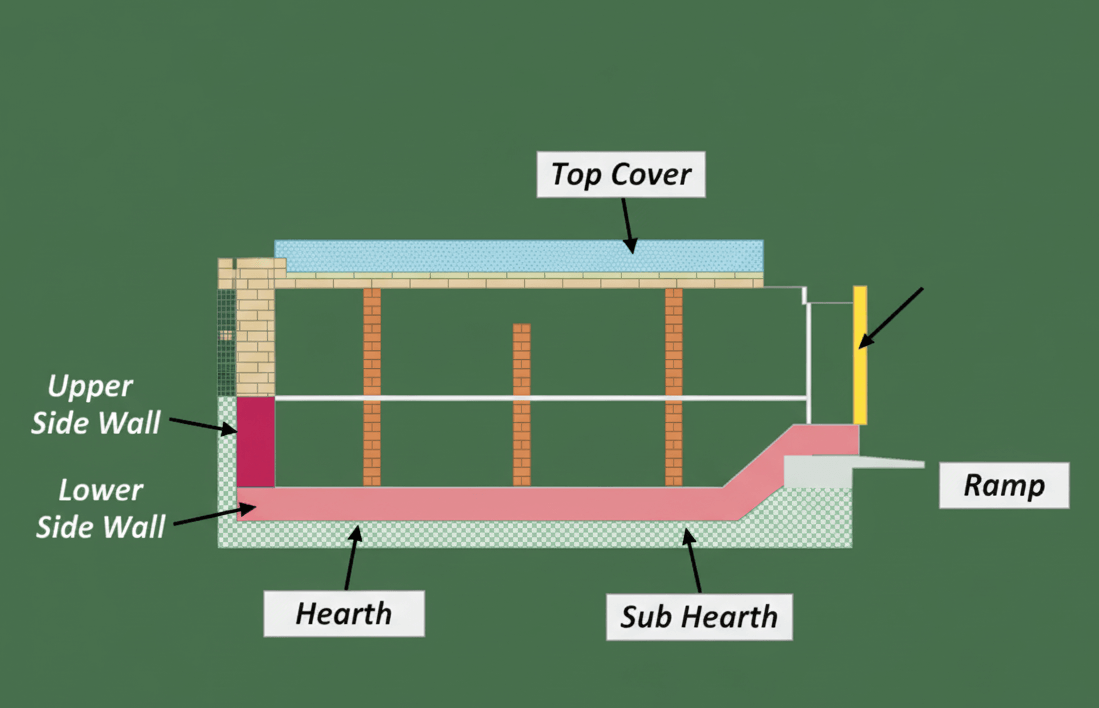

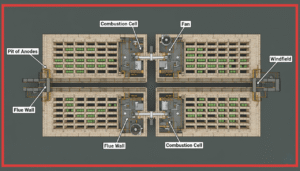

In Anode Backing Furnaces, our refractories ensure efficient heat transfer and dimensional stability under cyclic heating. For Holding and Melting Furnaces, we supply high-quality High Alumina Bricks, Insulating Bricks, and Castables that offer superior resistance to molten metal attack and maintain structural integrity at elevated temperatures. In Pot Furnaces, our materials provide excellent thermal insulation and resistance to chemical corrosion from fluxes and metal vapors.

With advanced manufacturing technology and proven performance across multiple Aluminium plants, Mahakoshal Refractories continues to deliver durable, energy-efficient, and customized refractory solutions, helping Aluminium producers achieve higher productivity, reduced downtime, and longer furnace life.

Key Refractory Application Areas in Aluminium Industries.

Refractories are vital for protecting equipment and ensuring reliable operations in Aluminium Industries. MRPL provides specialized refractory solutions designed to withstand extremely high temperatures, chemical corrosion, and mechanical wear in critical zones. Our products enhance durability, energy efficiency, and overall plant performance. Aluminium plant refractories are used across kilns, preheaters, coolers, and reaction zones to ensure consistent material processing and reduced operational interruptions.

WhatsApp UsEnhance Aluminium Industries Efficiency with MRPL Refractory Solutions

Benefits of Procuring Refractory Products from Mahakoshal Refractories

Own Mines

Own mines for sourcing clay and bauxite with strict quality control.

In-house Manufacturing

In-house manufacturing of high alumina cement for various castable grades.

Advance planning and sharp delivery commitments

Advance planning and sharp delivery commitments ensuring on-time dispatch – often up to ahead of schedule.

Real-time Shipment Updates

Real-time shipment updates keeping customers informed throughout transit.

Reliable & Transparent Service

Reliable and transparent service at every stage of the supply process.

Quick & Efficient Response

Quick and efficient response to customer needs and requirements.

Strong Focus On Customer Satisfaction

Strong focus on customer satisfaction with complete post-delivery support.

Trusted Partnership

Trusted partnership built on timely delivery, quality assurance, and long-term reliability.

Why Aluminium Industries Rely on MRPL Refractories

Proven Experience

Decades of providing specialized refractory solutions to Aluminium and high-temperature industries globally.

Quality Assurance

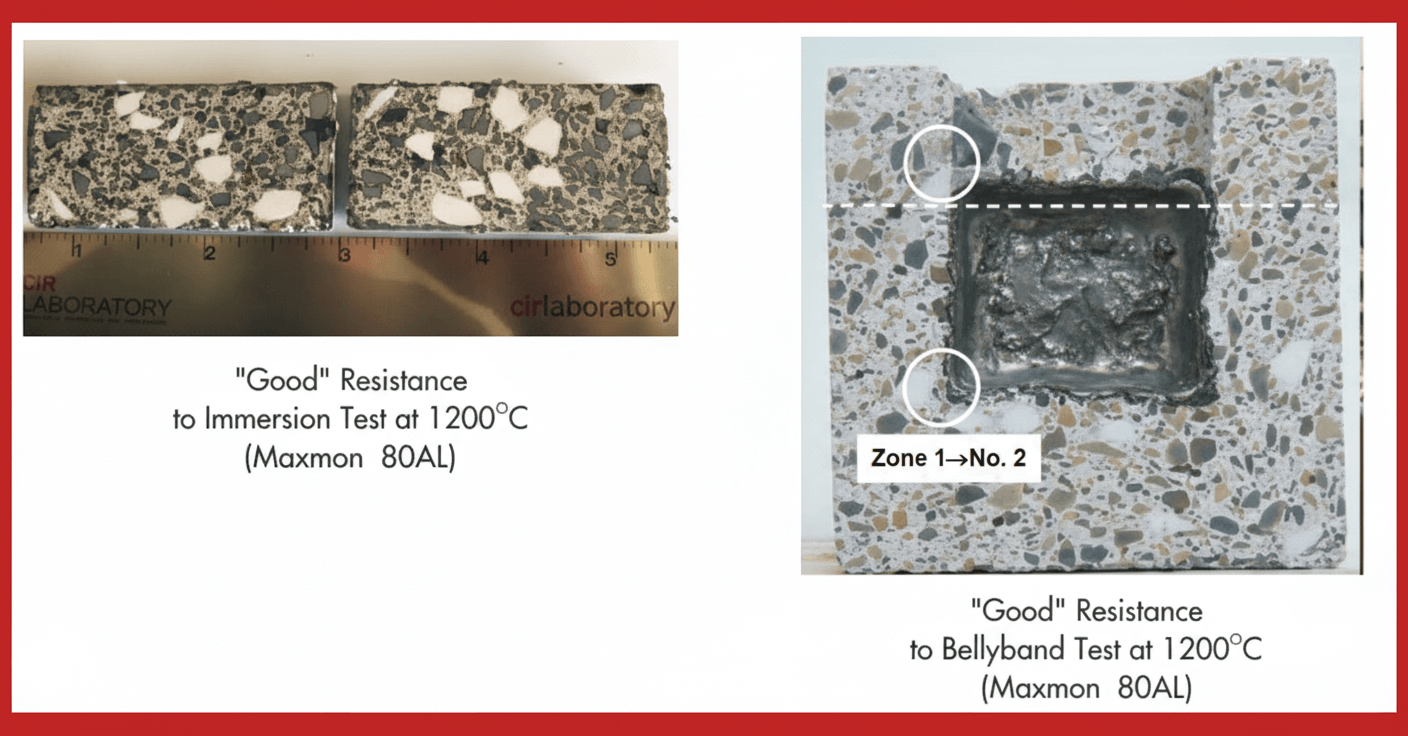

Rigorous testing ensures durable, high-performance, and thermally stable refractory products consistently.

Customized Design

Tailored refractory solutions meet unique Aluminium plant operational requirements for optimal efficiency.

On-Time Delivery (OTIF)

Efficient production and logistics guarantee timely supply of all refractory materials reliably.