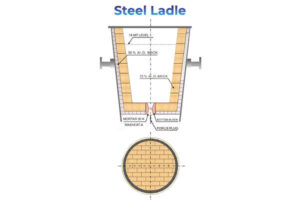

Expert Refractory Solutions for Steel Ladles

Durable, Efficient, and High-Performance Refractory Materials

Mahakoshal Refractories Pvt. Ltd. (MRPL) is a trusted refractory manufacturer for Steel Ladle operations, delivering high-quality solutions that enhance durability, efficiency, and operational safety.

Our expertise covers critical areas such as kilns, preheaters, coolers, and high-temperature zones where molten steel is handled and transferred. MRPL specializes in high alumina bricks, refractory castables for Steel Ladle kilns, and customized refractory solutions engineered to withstand extreme thermal, chemical, and mechanical stresses.

Our products reduce downtime, optimize energy consumption, and ensure consistent performance throughout steel handling processes. By providing reliable refractory solutions, we help Steel Ladle operators extend equipment life, minimize maintenance costs, and maintain continuous production.

MRPL collaborates closely with clients to design and supply refractory materials tailored to specific operational requirements, ensuring structural integrity, thermal efficiency, and safety in all critical zones. With a strong focus on quality, innovation, and customer satisfaction, MRPL supports Steel Ladle industries in achieving sustainable, high-efficiency operations through advanced refractory technology.

Key Refractory Application Areas in Steel Ladle.

Refractories play a crucial role in Steel Ladles by protecting equipment, ensuring thermal efficiency, and maintaining safe molten steel operations. MRPL provides specialized refractory solutions designed to withstand extreme temperatures, chemical attack, and mechanical wear in all critical zones. Our products enhance durability, energy efficiency, and operational reliability. Steel Ladle refractories are used in kilns, ladle linings, and molten steel transfer zones to ensure uniform heating, minimal thermal loss, and uninterrupted production. By deploying high-quality refractory materials, MRPL helps operators extend equipment life, reduce maintenance, and optimize energy consumption. From ladle filling to pouring and tapping, our refractory solutions provide long-term protection, consistent performance, and safeguard investments in critical Steel Ladle infrastructure.

WhatsApp UsEnhance Steel Ladle Efficiency with MRPL Refractory Solutions

Key Benefits of MRPL Refractory Solutions for Steel Ladles

Enhanced Durability

High alumina bricks and castables withstand extreme heat and chemical corrosion effectively.

Energy Efficiency

Steel Ladle refractory solutions reduce fuel consumption and optimize thermal performance consistently.

Cost-Effectiveness

Long-lasting refractory materials minimize maintenance and replacement expenses for ladle operations.

Reliable Performance

Robust refractory solutions ensure continuous operation and uniform molten steel handling processes.

Why Steel Ladle Industries Trust MRPL Refractories

Proven Experience

Decades of providing specialized refractory solutions to Steel Ladle industries worldwide.

Quality Assurance

Rigorous testing ensures durable, high-performance, and thermally stable refractory products consistently.

Customized Design

Tailored refractory solutions meet unique operational requirements for maximum ladle efficiency.

On-Time Delivery (OTIF)

Efficient production and logistics guarantee timely supply of refractory materials reliably.