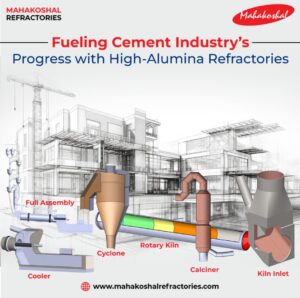

Refractory Solutions for the Cement Industry by MRPL

Enhancing Kiln Efficiency and Durability with Trusted Refractory Materials

Mahakoshal Refractories Pvt. Ltd. (MRPL) is a leading manufacturer and supplier of high-performance refractory solutions for the cement industry. With more than five decades of expertise, MRPL provides a complete range of fired bricks, shaped products, and advanced monolithic refractories designed to perform reliably in rotary kilns, preheaters, calciners, and clinker coolers.

Our refractories are engineered for maximum durability, superior heat resistance, and cost-efficient lining performance under extreme operating conditions. They effectively resist abrasion, alkali attacks, and severe chemical corrosion, making them ideal for modern cement plants, including those using alternative fuels.

At MRPL, innovation drives progress. We continuously develop next-generation refractory materials and easy-to-apply monolithic systems including casting, gunning, and ramming mixes that ensure smooth installation and longer service life.

Supported by a team of experienced engineers and application experts, MRPL offers complete refractory design, installation, and maintenance services for troubleshooting, retrofitting, and turnkey projects. Our holistic approach helps cement manufacturers enhance kiln efficiency, reduce downtime, and achieve sustainable, long-term performance across all stages of cement production.

Key Refractory Application Areas in Cement Plants.

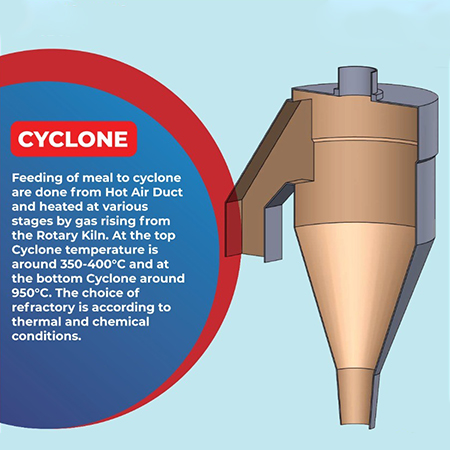

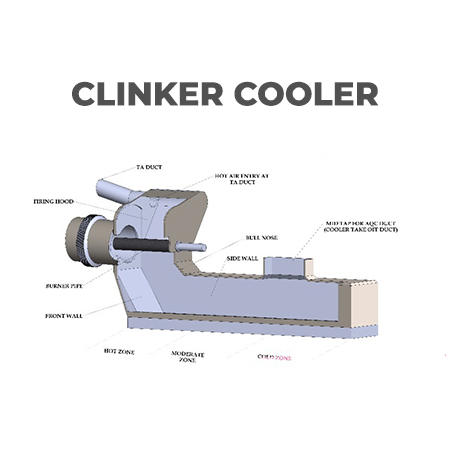

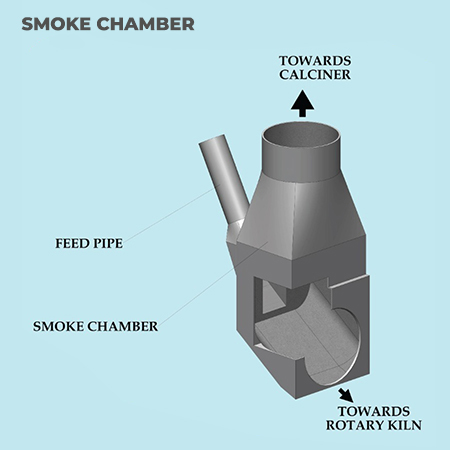

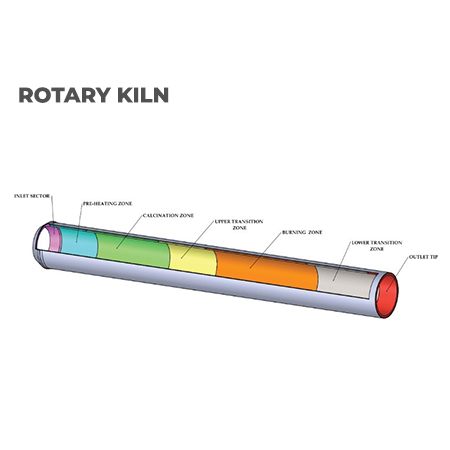

Cement plants operate under high temperatures and abrasive environments, making reliable refractory linings essential for efficiency and safety. MRPL’s range of refractories is specifically designed to handle the demanding conditions in cement production units. Our advanced materials are used in rotary kilns, preheaters, clinker coolers, and other process zones to ensure consistent heat distribution, reduced energy loss, and longer equipment life. With customized solutions for each area of application, MRPL helps cement manufacturers achieve optimal performance, lower downtime, and improved cost efficiency.

WhatsApp UsGet a Custom Refractory Solution for Your Cement Plant Today

Benefits of Procuring Refractory Products from Mahakoshal Refractories

Own Mines

Own mines for sourcing clay and bauxite with strict quality control.

In-house Manufacturing

In-house manufacturing of high alumina cement for various castable grades.

Advance planning and sharp delivery commitments

Advance planning and sharp delivery commitments ensuring on-time dispatch – often up to ahead of schedule.

Real-time Shipment Updates

Real-time shipment updates keeping customers informed throughout transit.

Reliable & Transparent Service

Reliable and transparent service at every stage of the supply process.

Quick & Efficient Response

Quick and efficient response to customer needs and requirements.

Strong Focus On Customer Satisfaction

Strong focus on customer satisfaction with complete post-delivery support.

Trusted Partnership

Trusted partnership built on timely delivery, quality assurance, and long-term reliability.

Why Choose MRPL for Cement Industry Refractories

Proven Industry Expertise

With decades of experience, MRPL delivers reliable refractory solutions tailored to cement plant operations and processes.

Advanced Manufacturing Facilities

State-of-the-art kilns, presses, and testing labs ensure precision-engineered refractories meeting global cement industry standards.

Reliable Raw Material Sourcing

In-house bauxite and clay mines guarantee consistent raw material quality and uninterrupted refractory supply chain.

Global Reach & Support

Serving leading cement plants worldwide with timely delivery, expert technical assistance, and performance-driven refractory products.