High-Performance Plastics Masses Double Component for Industrial Refractories

About Plastics Masses (Double Component)

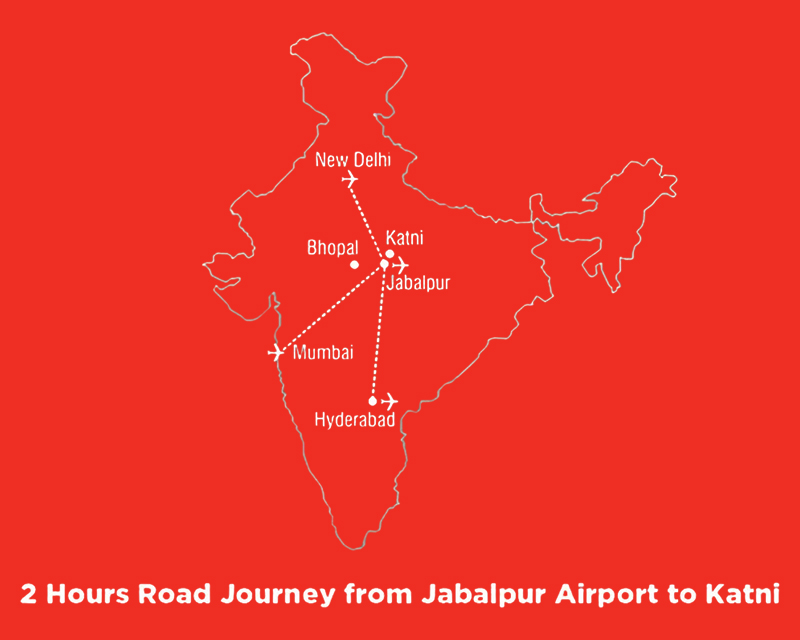

Mahakoshal Refractories Pvt. Ltd. (MRPL) is a trusted manufacturer of Plastics Masses (Double Component), producing both medium and high purity variants since 2004. Strategically located in a bauxite- and limestone-rich region, with captive bauxite mines, MRPL ensures cost-effective production without compromising quality. Our double-component plastic masses are specifically engineered for unshaped refractory applications, offering superior bonding, thermal stability, and ease of installation.

MRPL’s plastics masses are extensively used in kilns, preheaters, coolers, and clinker formation zones, providing high durability, thermal efficiency, and resistance to abrasion and chemical attack. Designed for high alumina bricks, refractory castables, and custom furnace linings, these double-component masses ensure uniform density, minimal shrinkage, and long service life. Backed by dedicated quality control and testing facilities, MRPL delivers products that meet international standards while offering energy-efficient, cost-effective, and high-performance refractory solutions for Plastics Masses (Double Component) kilns. Trusted by MNCs and domestic manufacturers, our plastics masses provide the technical edge for industries requiring reliable unshaped refractories.

Serving Industries with Plastics Masses (Double Component).

MRPL’s Plastics Masses (Double Component) refractories serve industries demanding high-performance, durable, and energy-efficient unshaped products. Ideal for steel, cement, petrochemical, power, aluminium, and marine sectors, these products protect kilns, preheaters, coolers, and clinker formation zones from extreme temperatures and mechanical stress. Manufactured using premium raw materials and advanced formulations, MRPL ensures long service life, reduced maintenance, and improved operational efficiency. Our tailored solutions meet international standards, providing reliable refractory solutions for Plastics Masses Double Component kilns across various applications, from furnaces to industrial reactors, supporting both domestic and multinational clients with cost-effective, high-performance unshaped refractories.

WhatsApp UsUpgrade Your Kiln Efficiency with MRPL Plastics Masses (Double Component)

Benefits of MRPL Refractories for Plastics Masses (Double Component)

Superior Bonding

Ensures excellent adhesion in kiln linings, high alumina bricks, and refractory castables applications.

High Durability

Engineered for long-lasting performance in Plastics Masses Double Component refractory solutions.

Energy Efficiency

Reduces heat loss, improving thermal performance in kilns, preheaters, and clinker formation zones.

Cost-Effective Performance

Minimizes maintenance, downtime, and operational costs while maintaining superior refractory performance.

Get in Touch

At Mahakoshal Refractories, we value every connection. Whether you’re looking for product information, technical support, or business collaboration, our team is ready to assist you. Get in touch with us through phone, email, or the form below – we’ll respond promptly to your requirements.