High-capacity plants, integrated raw material sourcing, and R&D-driven solutions for global refractory needs.

Facilities Backed By Technology And Trust

At Mahakoshal Refractories Pvt. Ltd. (MRPL), our facilities are designed to combine scale, precision, and innovation. With decades of expertise and continuous investments in infrastructure, we have built an integrated setup that supports every stage of refractory production – from raw material sourcing to final application.

At Mahakoshal Refractories Pvt. Ltd. (MRPL), our facilities are designed to combine scale, precision, and innovation. With decades of expertise and continuous investments in infrastructure, we have built an integrated setup that supports every stage of refractory production – from raw material sourcing to final application.

Our operations are strengthened by captive mines, ensuring consistent availability of high-quality raw materials and complete control over mineral processing. Advanced calcination units, high-capacity presses, and modern kilns enable us to manufacture a wide range of shaped and unshaped refractories with uniformity and reliability. Each plant is equipped with dedicated laboratories and R&D facilities, where our technical teams conduct rigorous quality checks, trials, and product development to meet evolving industry demands.

To maintain international standards, MRPL has invested in automation, energy-efficient technologies, and sustainable practices such as dust collection systems, rainwater harvesting, and green energy initiatives. These efforts not only improve operational efficiency but also reflect our commitment to environmental responsibility.

Our facilities are strategically located in Katni (Madhya Pradesh) and Bhachau (Gujarat), allowing us to serve diverse industries across India and overseas with speed and efficiency. The infrastructure also supports specialized services through our Refracare Engineering division, which focuses on design, application, and total refractory management.

By combining world-class infrastructure with technical expertise, MRPL ensures that every product leaving our facilities upholds the promise of durability, performance, and trust.

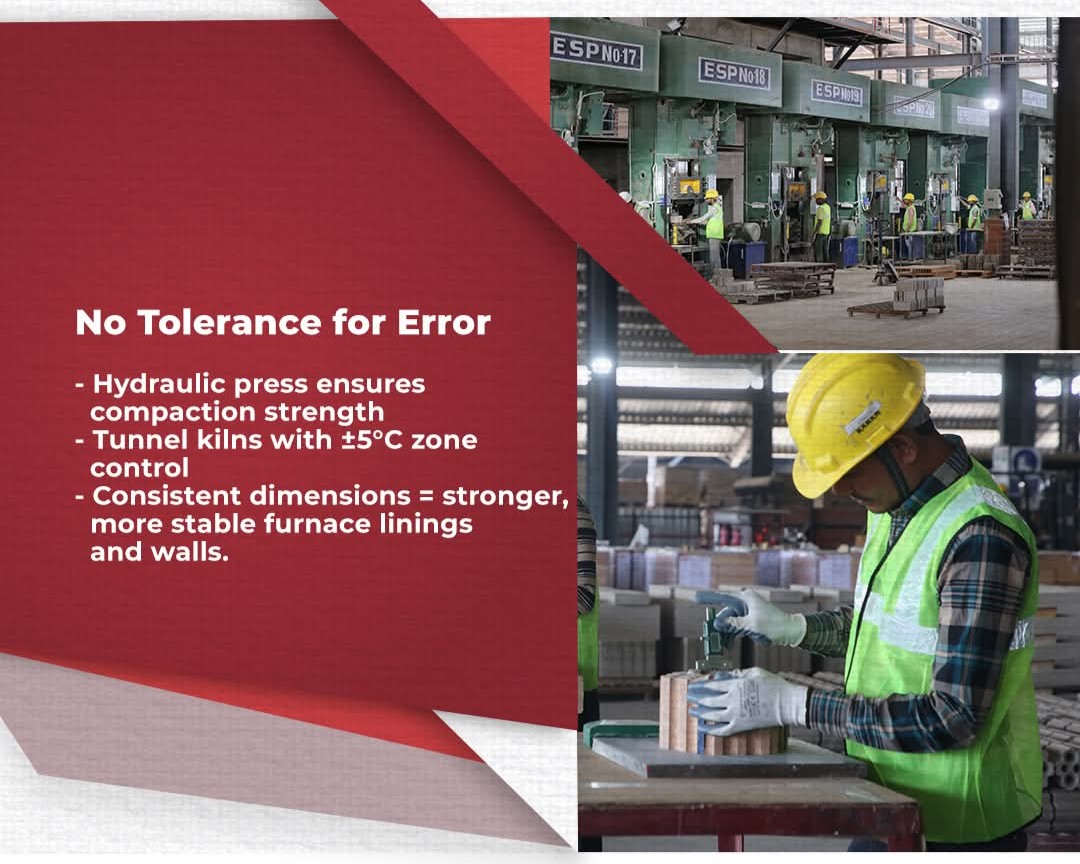

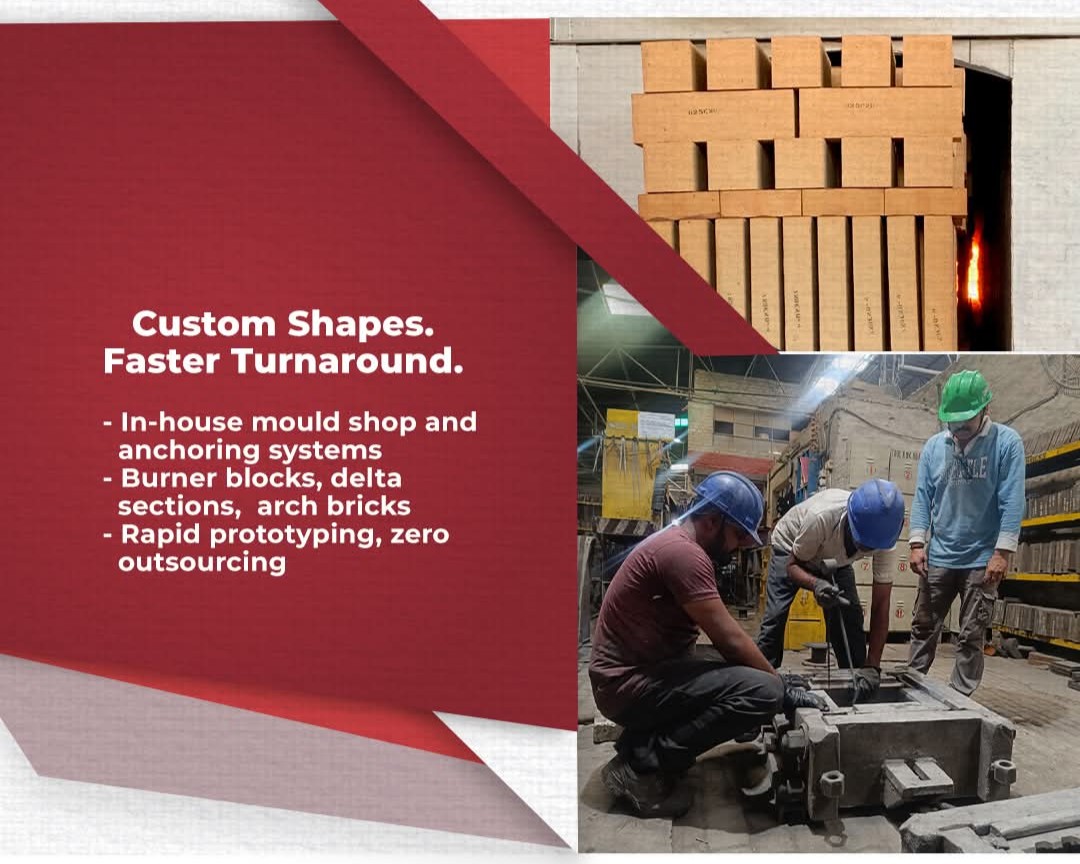

Manufacturing Units

MRPL operates state-of-the-art manufacturing units in Katni, Madhya Pradesh, and Bhachau, Gujarat, with a combined production capacity of over 300,000 MT annually. These facilities are equipped with modern kilns, high-capacity presses, automated handling systems, and advanced processing lines, enabling the delivery of high-quality refractories to diverse industries in India and overseas. Our backward integration gives us a strong edge through captive mines, calcination facilities, and in-house high alumina cement production, ensuring quality control from raw material to finished products. Each unit is backed by advanced laboratories and R&D centers, fostering innovation, continual improvement, and world-class refractory solutions.

Production Capacity

MRPL operates with an impressive annual production capacity exceeding 317,400 MT, positioning itself among the top refractory manufacturers in India. Our state-of-the-art units are equipped to produce a wide variety of shaped and unshaped refractories, such as high alumina bricks, castables, mortars, and flow control products, ensuring reliability and consistency across industries. In addition, we maintain specialized capacities including 200 MT of stainless steel anchors, 30,000 MT of calcined minerals, and 12,000 MT of synthetic aggregates. This scale of production, backed by advanced technology and strict process controls, enables us to meet diverse requirements with timely delivery and superior quality.

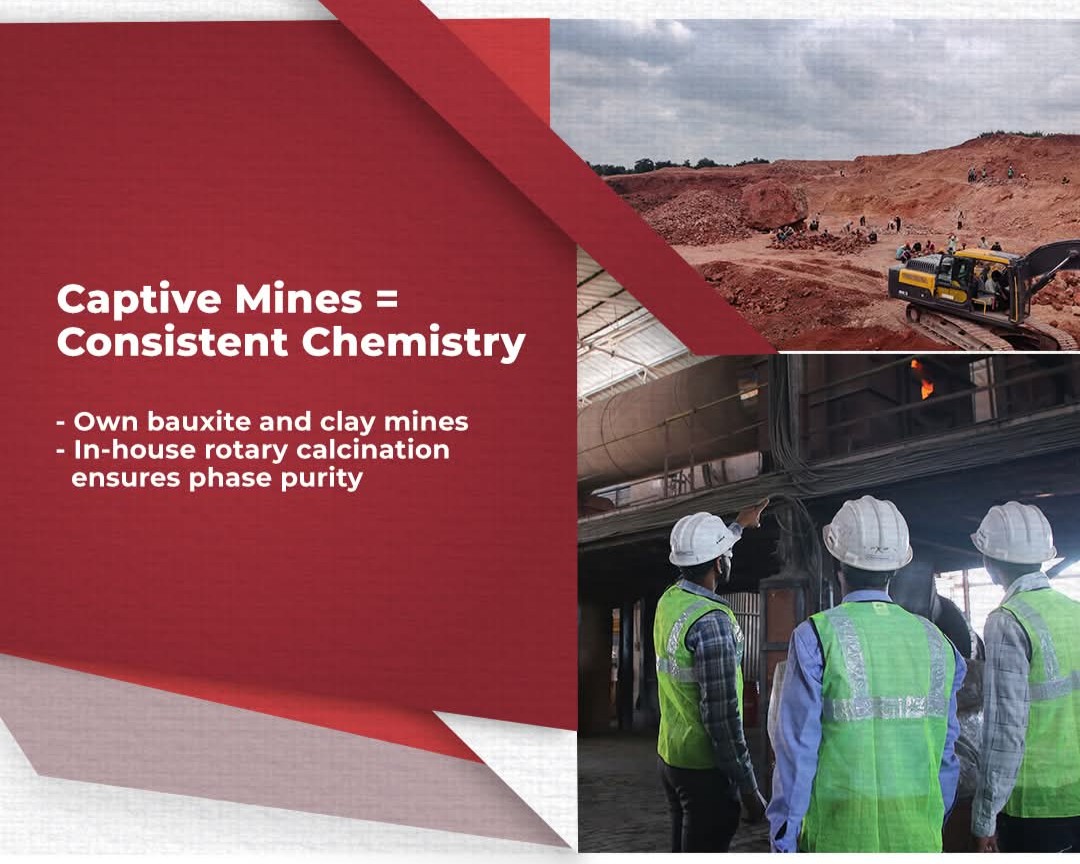

Backward Integration

MRPL has a unique strength in backward integration, sourcing high-quality raw materials from its own captive mines. This ensures uninterrupted supply of key inputs like fireclay and high alumina minerals, giving us greater control over consistency, cost, and quality. By managing raw materials in-house, we reduce dependency on external sources and safeguard our customers against supply chain disruptions. Our integration extends further with facilities for calcined minerals and synthetic aggregates, along with in-house high alumina cement production. This self-reliant model not only supports large-scale manufacturing but also guarantees superior product performance tailored to industry-specific applications.

Research & Development (R&D)

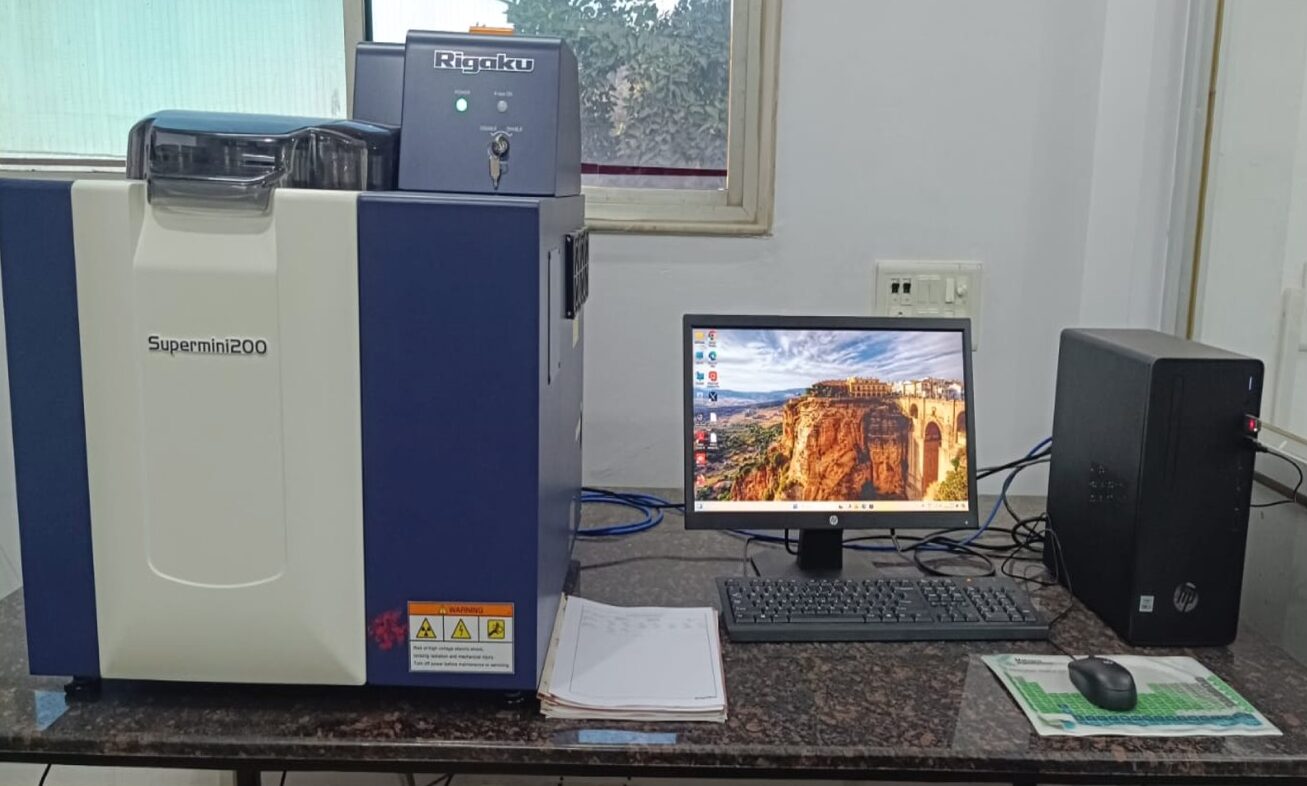

MRPL places strong emphasis on Research & Development (R&D) to stay ahead in the global refractory industry. A dedicated R&D center, equipped with advanced testing and analytical facilities, enables continuous innovation in refractory design, raw material development, and performance enhancement. The team focuses on improving durability, thermal efficiency, and cost-effectiveness to meet the evolving needs of diverse industries. Our R&D initiatives have led to the development of new-generation flow control products and customized refractory solutions for steel, cement, and other high-temperature processes. Ongoing investment in infrastructure, technology, and skilled researchers ensures MRPL consistently delivers high-performance, future-ready solutions.

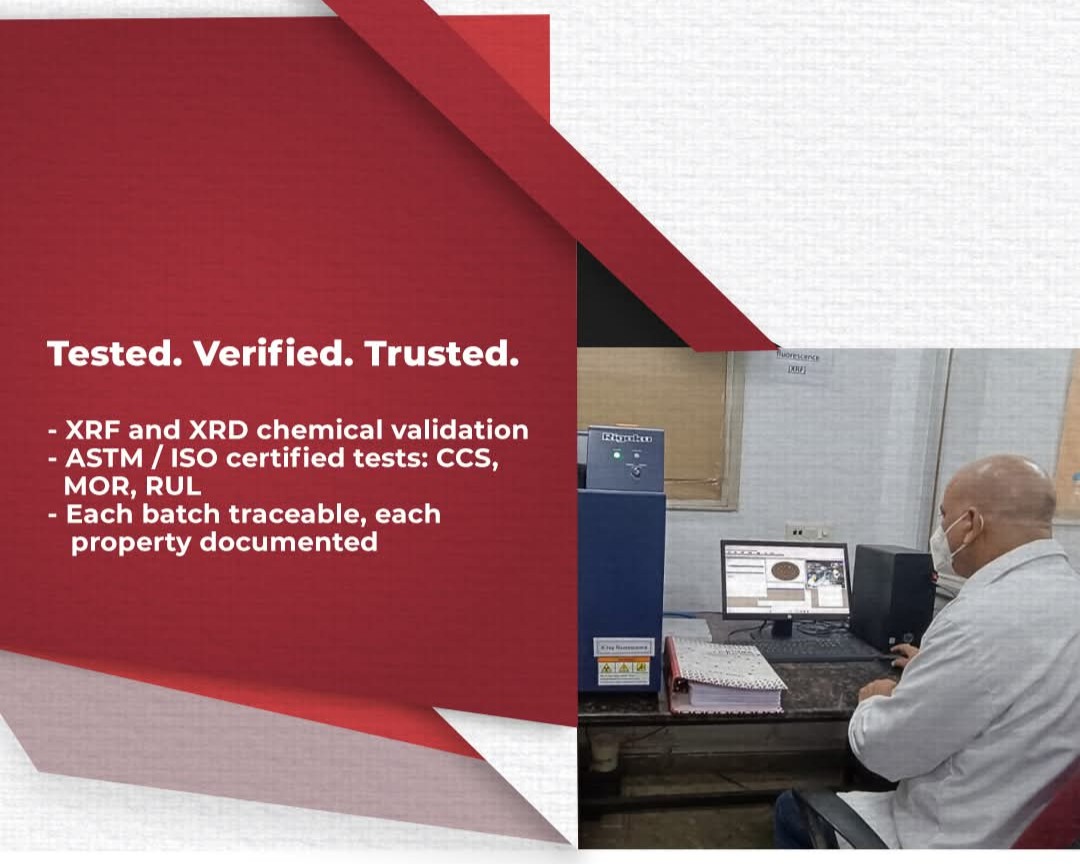

Testing & Quality Control

At MRPL, quality control is built into every stage of the manufacturing process, from raw material selection to final product dispatch. A fully equipped laboratory with modern instruments ensures that each batch undergoes rigorous physical, chemical, and thermal testing. This guarantees consistency, reliability, and compliance with global quality standards. Our dedicated quality assurance team monitors performance through routine inspections, audits, and trial protocols at customer sites. By combining strict testing methods with continuous improvement practices, MRPL ensures that every refractory product delivers maximum durability, efficiency, and value in high-temperature industrial applications.

Logistics & Warehousing

MRPL has developed a robust logistics and warehousing system to ensure smooth handling, safe storage, and timely delivery of refractory products across India and international markets. Modern warehouses near manufacturing units are equipped with proper material handling systems and inventory controls, ensuring safe storage of both raw materials and finished goods. With an efficient logistics network and tie-ups with reliable transport partners, MRPL is able to meet urgent requirements and maintain uninterrupted supply to diverse industries. This integrated approach helps minimize lead times, reduce costs, and provide customers with dependable, on-time deliveries.

Sustainability & HSE Facilities

MRPL places sustainability and safety at the core of its operations, integrating Health, Safety, and Environment (HSE) practices into every stage of manufacturing. Advanced facilities such as dust collectors, scrubbers, rainwater harvesting, and solar energy systems are deployed to reduce emissions and conserve resources. Green cover development and energy-efficient equipment further strengthen its commitment to environmental protection.

Alongside sustainability, MRPL maintains world-class safety standards for its workforce. With ISO 45001:2018 certification, the company ensures risk identification, pollution control, workplace safety programs, and continuous training. These measures build a secure, compliant, and eco-conscious work environment for employees and communities.